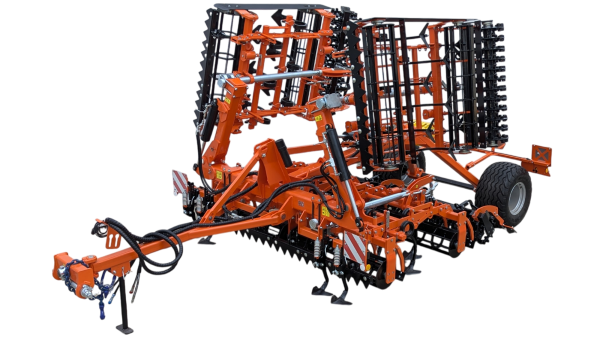

Characteristics

- Working width:6,0

- Working speed:8-12

- Performance:3.8-6.8

- Tractor power:180

- The weight:5500

- Maximum working depth:40-120

Description

Description Loosening the tractor track.

Preliminary soil processing with the front roller. The front roller crushes clods on the surface.

re-crumbling.

The unit performs up to 8 operations in one pass:

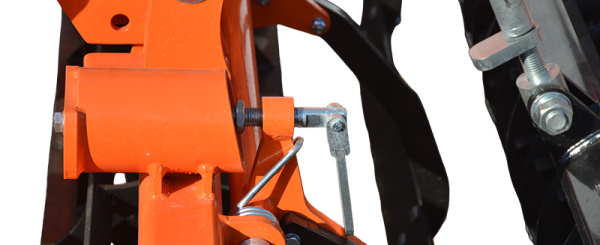

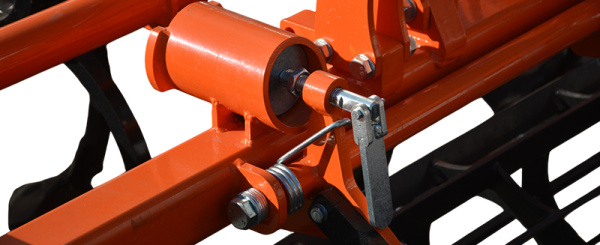

The height of the wrapper controls the size of the fraction of soil that should remain behind the roller.

- Formation of the sowing bed. Loosening and cutting of weeds with arrow or chisel tines to the specified depth. The depth should be the same as the sowing depth. When using the chisel shares, the soil is cut over the entire area and weeds are destroyed.

- The wrapper behind the rear crumbling roller regulates the size of the soil fraction that should remain behind consolidation roller.

- Soil compaction with the rear roller. The roller finely crushes the remaining clods and provides the final Preparation of the seedbed with a fully restored soil structure.

Restoration of soil capillarity draws moisture to the surface for uniform germination even in dry periods.

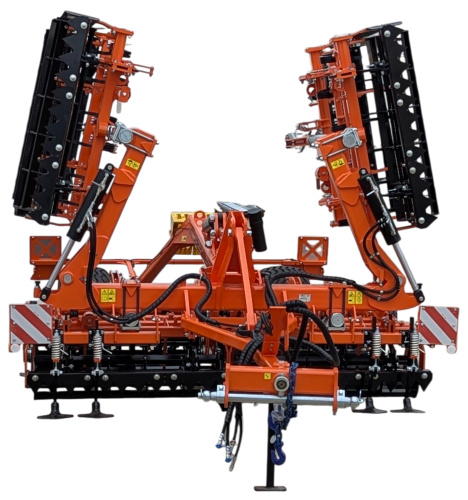

For better cultivation of uneven fields, the compactor has independent sections with a width of only 1.5 or 2 metres. Each section is suspended from the frame by a rigid rod, which gives it 3 degrees of freedom (oscillation along the rod, oscillation perpendicular to the rod, and up and down translational movements).

FAQ