Rotary harrows Favorite of the BRF "Gonter" are designed for weed control on various types of soils, especially on highly compacted soils with continuous and inter-row processing of any crops: grain, row crops, legumes, vegetables, etc.

The tool allows you to perform a number of tasks with high productivity, which are an integral part of professional soil treatment. It is used most often in regions where there is a lack of moisture, to ensure moist preservation, as well as to fight weeds (in the thread stage), destroy the crust, loosen the surface of the field (to prevent late germination of grain), saturate the soil with air, preserve moisture , soil preparation for sowing. Similarly, loosening increases the porosity of the soil, thereby contributing to the uniform distribution of oxygen and moisture in the soil and thus, leads to the strengthening and growth of the plant and making it more resistant to drought. The unit effectively and evenly loosens the soil, without damaging the plants, and has a high frame, which allows for inter-row cultivation in the later stages of the growing season.

The working speed can vary from 10 to 16 km/h. (Recommended working speed 10-13km/h)

The rotary cultivator is used for processing plants with a height of 10 to 25 cm.

The rotary cultivator can also be used for inter-row processing of plants up to 60 cm high. To do this, it is necessary to increase the inter-row distance between the racks by removing the excessive number of racks with hoes with the selected row spacing (optional).

Optionally, the hoe post has an easy adjustment to set the row spacing by removing the spring from the post and raising the hoe post up and installing a stop pin that will hold the hoe.

The principle of operation of the hoe of the rotary cultivator is that due to the high speed of their rotation, the curved teeth of the hoe enter the ground almost straight, and exit at an angle, as a result of which they break (create micro disruptions) the soil. This action leaves the root system of cultivated plants intact, while the weeds break out with their roots to the surface and dry out.

Hoes with a diameter of 53 cm have a riveted structure that gives them strength, and they rotate on sealed bearings with a profile that prevents dust and moisture from entering. For greater durability, caps are installed on the open sides of the bearing to protect against direct ingress of debris, soil, and moisture.

The unique cast hoe racks have a configuration that allows you to copy the terrain as accurately as possible and protects the hoe from stones and other obstacles. Each hoe is mounted on its own cast rack, which is independently spring-loaded from the others. Thanks to this rack, you will be able to process a larger area in a day. Short and long cast posts pivot the hoes by 17 cm, which makes it easier to process crop residues.

The tooth has the shape of the beak of a spoon with a geometry that wears less during operation and lasts longer than analogues.

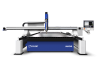

The general view of the harrow in the working position is shown in Figure 1.

Processing is carried out along the entire width of the tool, with any amount of plant residues and does not clog. This unit is designed according to the scheme of a spring-loaded oscillating lever.

The quality of processing depends on the speed, and the higher it is, the stronger the tool loosens the soil, breaking it up.

The flexibility of the levers is provided by a spring that exerts a pressure of approximately 25 kg on the soil.